Rebuild your Hemi with confidence using instruction from long-time Mopar engineer, racing coordinator and veteran author Larry Shepard.

In New Hemi Engines 2003-Present: How to Rebuild, Shepard delivers thorough instructions for each crucial step of the rebuilding process. Before commencing engine tear down, he shows you how to perform compression and leak down testing to accurately assess the health of the engine. Disassembly and comprehensive inspection instructions are provided so you can determine and remedy any underlying problems. Expert insight allows you to select the ideal parts package for your rebuild, whether OEM replacement or compatible and complementary high-performance parts are selected. The most pertinent information for the latest machining practices is provided, so you can coordinate with the machine shop to return the block, head, intake, and other surfaces to like-new condition. Assembling the cylinder heads as well as accurately measuring, checking clearances, and test fitting parts is detailed, so you’re sure all components are within spec and ready for final assembly. Finally, comprehensive step-by-step instructions are provided for assembling all components into a completed engine.

When Chrysler released the “new” third-generation Hemi engine in 2003, the automotive public placed high expectations on the Hemi’s triumphant return. The Hemi Gen III 5.7L, 6.1L, and 6.2L supercharged and 6.4L engines didn’t disappoint; they produced copious amounts of horsepower and torque while delivering exceptional durability. These powerful engines occupy the engine bays of new Challengers, Chargers, Magnums, 300Cs, Durangos, Jeep Grand Cherokees, and Ram trucks. Many of these engines have been used for high-performance service or logged hundreds of thousands of road miles, and as a result, many need to be rebuilt.

The modern Hemi engine is lighter and stronger and offers far better drivability and performance than its predecessors. However, after hundreds of thousands of miles, extreme use, or high-performance applications, these rugged engines require a professional-caliber rebuild. With this book, you can confidently complete your Hemi rebuild and get your car or truck back into action.

From the Publisher

Larry Shepard delivers thorough instructions for each crucial step of the rebuilding process. He shows you how to perform compression and leak down testing to accurately assess the health of the engine. Disassembly and comprehensive inspection instructions are provided so you can determine and remedy any underlying problems. Expert insight allows you to select the ideal parts package for your rebuild, whether OEM replacement or compatible and complementary high-performance parts are selected. The most pertinent information for the latest machining practices is provided, so you can coordinate with the machine shop to return the block, head, intake, and other surfaces to like-new condition. Assembling the cylinder heads as well as accurately measuring, checking clearances, and test fitting parts is detailed, so you’re sure all components are within spec and ready for final assembly. Comprehensive step-by-step instructions are provided for assembling all components into a complete engine.

Is it Time to Rebuild?

There are several styles of compression gauges. This one has a short piece of hose that threads into the spark plug holes. The extra-long reach of the plug shouldn’t cause any problems as long as the O-ring seals to the plug seat.

Disassembly

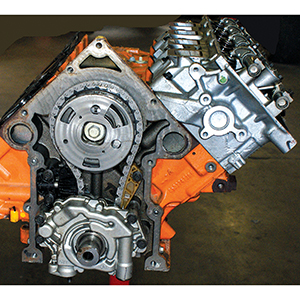

On the 2009 and newer engines with variable valve timing (VVT), the cam sprocket has a phaser attached to the front of the cam sprocket. The phaser replaces the windowed dish. Do not remove the phaser from the cam sprocket.

Inspection

The machine shop will use a dial-bore gauge to measure the exact bore size of each cylinder. The dial-vernier can give you a quick answer if there is a question relating to the block being overbored at an earlier date or previous rebuild or a 5.7L block being passed off as a larger version.

Because the Gen III Hemi is shorter, narrower, and much lighter than earlier Hemis, it makes a great engine swap choice (an A-body shown). The close shock towers presented a problem for the Gen II Hemi and RB big-blocks.

Parts Selection

The aftermarket offers many Gen III Hemi cranks from basic service to 4.00- to 4.050-inch strokers. The rods and pistons must be matched to the crank for stroker applications. The crank wheel must match the sensor mounted in the block and the ECM that is in the vehicle.

Machining

The machine shop will usually return the block with the main caps installed. The main caps have cast-in numbers or were marked at disassembly. Unless the engine suffered a failure, there is no reason to change the main caps.

Final Assembly

Measure the crank end play and record. Do this after the piston and rod assemblies are installed. Set the dial indicator on the pan rail with the indicator on the flat face of a counterweight and somewhat parallel to the crank centerline.

Publisher : CarTech

Publication date : February 2, 2019

Edition : Illustrated

Language : English

Print length : 144 pages

ISBN-10 : 1613254474

ISBN-13 : 978-1613254479

Item Weight : 2.31 pounds

Dimensions : 8.5 x 0.38 x 11 inches

Part of series : Performance How-To

Customers say

Customers find the book provides good information about the gen 3 hemi engine, with one customer noting it includes details on design features and modification options. The book receives positive feedback for its value, with customers saying it’s worth the price, and they appreciate the good pictures throughout. The readability receives mixed reviews.

![Pinnacle Studio 26 Ultimate | Pro-Level Video Editing & Screen Recording Software [PC Key Card]](https://m.media-amazon.com/images/I/81NS+ieWQpL._AC_SL1500_.jpg)

There are no reviews yet.